Distributed by:

Equipment Overview | Filter Pump Industries / Penguin Pump | Process Technology

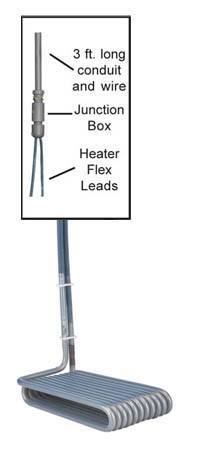

HXOL Series, Flex Riser Fluoropolymer (PTFE) Heaters

| Watts | Volts | Width In./(mm) |

Overall Length In./(mm) |

Model Number | Ship Weight Lbs./(kg) |

|---|---|---|---|---|---|

| 1000 | 120 240 |

2 (50) | 11 (280) | HXOL1102-11L-** HXOL1202-11L-** |

6 (2.5) |

| 1000 | 120 240 |

4 (100) | 8 (205) | HXOL1104-08L-** HXOL1204-08L-** |

6 (2.5) |

| 2000 | 120 240 480 |

4 (100) | 13 (330) | HXOL2104-13L-** HXOL2204-13L-** HXOL2404-13L-** |

7 (3.5) |

| 2000 | 120 240 480 |

5 (125) | 10 (255) | HXOL2105-10L-** HXOL2205-10L-** HXOL2405-10L-** |

7 (3.5) |

| 2000 | 120 240 480 |

6 (155) | 8 (205) | HXOL2106-08L-** HXOL2206-08L-** HXOL2406-08L-** |

7 (3.5) |

| 3000 | 240 480 |

4 (100) | 18 (460) | HXOL3204-18L-** HXOL3404-18L-** |

12 (5.5) |

| 3000 | 240 480 |

5 (125) | 12 (305) | HXOL3205-12L-** HXOL3405-12L-** |

12 (5.5) |

| 3000 | 240 480 |

6 (155) | 11 (280) | HXOL3206-11L-** HXOL3406-11L-** |

12 (5.5) |

| 3000 | 240 480 |

8 (205) | 8 (205) | HXOL3208-08L-** HXOL3408-08L-** |

12 (5.5) |

| 4000 | 240 480 |

5 (125) | 18 (460) | HXOL4205-18L-** HXOL4405-18L-** |

14 (6.5) |

| 4000 | 240 480 |

6 (155) | 14 (355) | HXOL4206-14L-** HXOL4406-14L-** |

14 (6.5) |

| 4000 | 240 480 |

8 (205) | 11 (280) | HXOL4208-11L-** HXOL4408-11L-** |

14 (6.5) |

| 5000 | 240 480 |

6 (155) | 18 (460) | HXOL5206-18L-** HXOL5406-18L-** |

17 (8) |

| 5000 | 240 480 |

8 (205) | 13 (330) | HXOL5208-13L-** HXOL5408-13L-** |

17 (8) |

| 5000 | 240 480 |

9 (230) | 11 (280) | HXOL5209-11L-** HXOL5409-11L-** |

17 (8) |

| 5000 | 240 480 |

10 (255) | 10 (255) | HXOL5210-10L-** HXOL5410-10L-** |

17 (8) |

| 6000 | 240 480 |

7 (180) | 18 (460) | HXOL6207-18L-** HXOL6407-18L-** |

20 (9) |

| 6000 | 240 480 |

8 (205) | 15 (380) | HXOL6208-15L-** HXOL6408-15L-** |

20 (9) |

| 6000 | 240 480 |

9 (230) | 13 (330) | HXOL6209-13L-** HXOL6409-13L-** |

20 (9) |

| 6000 | 240 480 |

10 (255) | 12 (305) | HXOL6210-12L-** HXOL6410-12L-** |

20 (9) |

| 6000 | 240 480 |

11 (280) | 11 (280) | HXOL6211-11L-** HXOL6411-11L-** |

20 (9) |

Features and Benefits

SUPERIOR CHEMICAL RESISTANCE:- Inert to most aqueous acid, alkaline, anodizing and pickling solutions up to 212°F (100°C).

- Heavy wall fluoropolymer (PTFE) covered stainless steel element reduces permeation and eliminates the need for gas purged systems. Guaranteed 100% pinhole free.

- Low watt density design (10 watts/square inch, 1.5 w/cm2) for long service life.

- 4-foot (1.2m) continuous fluoropolymer (PTFE) cable leading to a vapor resistant PVC terminal enclosure with 3-foot (.9m) flexible PVC liquid tight conduit.

- Grounded internal metal element.

- Thermal protector built in. Resettable P3 J-type thermocouple standard.

- Non-floating construction.

- UL listed to U.S. and Canadian safety requirements, and CE.

- 1,000 watts to 6,000 watts.

- 120 to 600 volts. Single phase only.

CONSULT FACTORY FOR THE FOLLOWING:

- Longer fluoropolymer (PTFE) riser lengths.

- Rigid riser with vapor resistant, flame retardant polypropylene terminal enclosure and either replaceable or resettable thermal protectors.

- Element "purge" option for chemicals that aggressively permeate fluoropolymer sheath.

- Special configurations.

- Longer wire and conduit lengths.

- Lower watt densities for highly viscous solutions and technical acids.

- Temperature and level controls sized to match the heater.

We recommend temperature controls and level controls for use with this immersion heater.

Downloads: