Filter Pump Industries - Penguin Pump

Equipment Overview | Filter Pump Industries / Penguin Pump | Process Technology

Filter Pump Industries - a division of Penguin Pumps, Incorporated.

Filter and Carbon Treatment chambers

Penguin filter chambers are offered in CPVC, polypropylene, and PVDF. The construction of the Series C chambers contains no fragile lucite or glass. There is no metal to liquid contact, no springs to lose or break, and no crushed tubes. Penguin CPVC and polypropylene chambers are recommended for most acid and alkaline solutions. PVDF chambers are recommended for high temperature acids and alkalies, HF, and electroless nickel. All Series C chambers can be mounted on a common polypropylene base and manifolded together for greater capacities or space saving requirements. For portability, casters can be added as an option. Penguin Series C double open end (D.O.E.) chambers are available in single tube, three tube, five tube, and twelve tube vessels. The Series C single open end (S.O.E.) chambers are available in single tube, two tube, four tube and nine tube vessels. Each D.O.E filter chamber is equipped with an initial Penguin 15 micron filter cartridge or set of filter cartridges. Filters for S.O.E chambers are purchased separately. Because of the unique Penguin design, these cartridges ensure maximum particle retention and no liquid bypass.

Features and Benefits:

- Leak Resistant

- Corrosion Resistant

- Unique Penguin design - No liquid bypasss / No external frame rods

- Removes solid dirt particles

- Quick change cartridge

- Choice of construction materials

- Uses filter cartridges submicronic pleated cartridges, or filter sleeves

Product Page:

Bulletins (PDF):

Penguin in-tank filter chambers allow for depth filtration that is completely limited to inside the tank. Thus, there is no possibility of solution loss in the Series CN chambers. The 3CN chambers are completely constructed of CPVC, polypropylene, and PVDF while the 6CN chambers are constructed of CPVC or polypropylene. This includes the rugged mounting bracket. Penguin models include single and three cartridge vessels in 10", 20", and 30" cartridge lengths. The Series CN chambers incorporate all of the unique construction advantages of our style 3C and 6C chambers. The cartridge compressor design in the style 3C chamber and the double labyrinth o-ring sealing, along with the long-sleeved flange on the top of style 6C, are also incorporated into our Series CN chambers.

Features and Benefits:

- Leak Resistant

- Corrosion Resistant

- Unique Penguin design - No liquid bypasss / No external frame rods

- Removes organic contaminants and solid dirt particles

- Easy conversion to filter chamber

- Choice of construction materials

- Choice of disposables - Carbon cartridge or bagged granular carbon

Product Page:

Bulletins (PDF):

Penguin carbon treatment chambers are available with carbon cartridges or bagged granular carbon. Each Series CT carbon cartridge chamber comes equipped with a Penguin Series PC disposable carbon cartridge containing pure, low sulfur, activated carbon granules. All carbon cartridges can be replaced with filter cartridges if straight filtration is required. Carbon bag chambers contain a reusable polypropylene mesh bag to be filled with Penguin style GC sulfur-free, activated granular carbon. Depending upon the style selected, the chamber holds from 5 to 100 pounds of carbon. When the carbon becomes exhausted, only the granular carbon, and not the bag, needs to be replaced. Penguin granular carbon quickly reaches its saturation point in absorbing minimal amounts of brighteners, yet continues to have excellent absorption for organic impurities. Following organic decontamination, the solution is automatically depth filtered through a 3 micron filter surrounding the core of the carbon cartridge or set of 3 micron filter cartridges attached to the carbon bag chamber head. This traps all foreign particles and solids. Carbon bag chambers can easily be converted to straight filtration if required. All carbon bag chambers come equipped with a flow plate, polypropylene mesh carbon bag, short and long filter cartridge rods, and an initial set of 3 micron filter cartridges used during carbon treatment.

Features and Benefits:

- Leak Resistant

- Corrosion Resistant

- Unique Penguin design - No liquid bypasss / No external frame rods

- Removes solid dirt particles

- Quick change cartridge

- Rugged CPVC construction including mounting bracket

- Complete in-tank filtration

Product Page:

Bulletins (PDF):

Penguin filter bag chambers are designed for high volume surface filtration. Completely constructed of CPVC, the Series CB filter bag chambers allow for filtration down to 1 micron. Filter bag replacement is easy with the removal of one snap ring. There are four sizes incorporating all of the construction advantages of our style 6C and 8C chambers. The double labyrinth o-ring sealing and the long-sleeved flanges, top and bottom, allow these chambers to operate at higher pressures and/or temperatures while eliminating the use of external frame rods

Features and Benefits:

- Leak Resistant

- Corrosion Resistant

- Unique Penguin design - No liquid bypasss / No external frame rods

- CPVC Construction

- Filtration down to 1 Micron

- Simple filter bag replacement

- High volume surface filtration

- Lower intial cost and reusable filter media

- Economical solution to a variety of corrosive filtration requirements

Product Page:

Bulletins (PDF):

Pumps

Penguin sealless vertical pumps are designed to handle a wide range of chemicals without difficulty. Completely constructed of CPVC, polypropylene, or PVDF where in contact with the solution being pumped, Series P pumps have an upper working temperature of 180/150/280° F, respectively, and thus can handle most corrosive, slurries, and abrasive solutions. Series P pumps are easy to install and operate. They have no seals or bushings, can run dry, and are virtually maintenance-free.

Features and Benefits:

- Choice of CPVC, PVDF, or Polypropylene

- Runs dry without damage

- Self-priming when immersed

- No metal contact

- Chemical-resistant

Product Page:

Bulletins (PDF):

Penguin Series P-HF CPVC vertical pumps are simple in design, efficient in performance, and self-priming when immersed in solution. With a double impeller design and no seals to leak or bushings or bearings to wear, this pump can run dry without damage while requiring little or no maintenance.

Features and Benefits:

- CPVC Construction

- Optional PVDF Impeller available

- No metal contact

- Chemical resistant

- Self-priming when immersed

- Dry run capability without damage

Product Page:

Bulletins (PDF):

Penguin horizontal centrifugal pumps are designed to handle a wide range of chemicals without difficulty. Completely constructed of CPVC where in contact with the solution being pumped, Series HV pumps have an upper working temperature of 180° F, and thus can handle most corrosive, slurries, and abrasive solutions. For high temperatures and very corrosive abrasive solutions, a double mechanical seal and water flush are supplied. For higher suction pressure, a single diplo internal seal is supplied.

Features and Benefits:

- True Volute design

- High efficiency

- Energy Saving

- Higher flow vs. pressure

- No metal contact

Product Page:

Bulletins (PDF):

Penguin magnetic-driven pumps are designed to handle a wide range of chemicals without difficulty. Constructed of polypropylene, kynar, or stainless steel, Series M pumps have an upper working temperature of 190/220/250° F, respectively, and thus can handle highly corrosive or mild chemicals, acids, or solvents. Series M pumps eliminate the conventional shaft seal found in most pumps. This means that there is no rotating seal to wear out and allow the liquid being pumped to leak out. The pumping action may eventually fail, however, the liquid can never leak out. Series M pumps are easy to install and operate, and are virtually maintenance-free.

Features and Benefits:

- Sealless

- No metal contact

- Bearing-free

- Chemical resistant

- Leak resistant

- Available in 316SS, Kynar, and Hastelloy

Product Page:

Bulletins (PDF):

Penguin self-priming sealless pumps offer the utmost in reliability, versatility, constant operating conditions, long working life, and practically maintenance-free operation. The only pump element subjected to natural wear is the flexible liner which, as with all other parts of the pump, can be easily replaced without the use of special tools. Series V pumps can be supplied with either a viton or neoprene liner, thus providing a pump which is resistant to most aggressive media such as the delivery of alkalines or acidiferous fluids, solvents, water of all grades of purity, waste water of all kinds, miscellaneous pharmaceuticals, galvanic fluids, solutions for the photo and film industry, fluids for the beverage and food industry, media for paper, textile and leather treatment, as well as paint and other coating media.

Features and Benefits:

- Wet or Dry operation

- No gasketst

- No shaft-seals

- Self-priming

Product Page:

Penguin multi-stage horizontal diffuser pumps are designed for higher pressure applications where a metallic pump is unacceptable. Constructed of CPVC, a 316SS shaft, and a metalless diplo seal, Series HD pumps are designed to handle a wide range of semi-corrosive chemicals without difficulty. An optional titanium shaft can be supplied for more corrosive solutions with an upper working temperature of 180° F.

Features and Benefits:

- Corrosion-resistant

- Optimum Efficiency

- Choice of three HP

- High pressure, utilizing smaller pump cases

- Diplo springless seal

Product Page:

Bulletins (PDF):

Penguin electronic metering pumps are positive displacement, non-hydraulic, solenoid driven, diaphragm type pumps. In the Series PB/PE/PEP pumps, the electronic circuitry is EMI resistant, incorporates automatic reset thermal overload protection, and employs a MOV for lightning protection. Pump drives are encased in water and chemical resistant housings. Most models are UL listed for outdoor and indoor applications and are CSA and NSF approved.

Features and Benefits:

- Series PB:

- Lowest cost alternative

- Manual function controls for stroke rate and length

- Series PE:

- Highly accurate digital timing circuit

- Thermally protected solenoid with auto-reset

- Series PEP:

- Panel mounted circuit breaker

Product Page:

Penguin 316 stainless steel centrifugal pumps are designed to handle a wide range of acids and alkalies as well as solvents to 250° F. For most conditions in the Series HSC pumps, the mechanical seal is cooled and lubricated by the liquid being pumped. Standard seals are supplied for suction pressures between 20 inches Hg vacuum and 85 psig, and liquid temperatures between -30° F and 211° F. Temperatures greater than 211° F, but less than 250° F, are acceptable for non-caustic, non-hydrocarbon service, but an optional seal assembly must be utilized.

Features and Benefits:

- Chemical-resistant

- Simplicity of Design

- High Operational Efficiency

- Easy maintenance

- Double seal with water flush

- Multi-Stage

Product Page:

Bulletins (PDF):

Penguin horizontal centrifugal pumps are designed to handle a wide range of semi-corrosive chemicals with little or no difficulty. Constructed of glass-filled polypropylene with a CPVC impeller in contact with the solution, Series HOM pumps have an upper working temperature of 150° F, and thus can handle many general industrial applications. A metalless internal diplo seal is supplied to allow for higher suction pressures.

Features and Benefits:

- Corrosion-resistant

- Optimum Efficiency

- Diplo Springless Seal

- Choice of 5 HP

- High Flow Rates

Product Page:

Bulletins (PDF):

Penguin horizontal volute pumps are designed for larger volume than the Series HV and are able to handle a wide range of chemicals without difficulty. Completely constructed of CPVC where in contact with the solution being pumped, Series HN pumps have an upper working temperature of 180° F, and thus can handle most corrosive, slurries, and abrasive solutions. For high temperatures and very corrosive abrasive solutions, a double mechanical seal and water flush are supplied.

Features and Benefits:

- Corrosion resistant

- Very high efficiency

- True volute design with center discharge

- No metal contact

- High flow rates

Product Page:

Penguin magnetic-driven pumps are designed for larger volume than the Series M and are able to handle a wide range of chemicals without difficulty. Constructed of polypropylene or PVDF, Series MT pumps have an upper working temperature of 180/220° F, respectively, and thus can handle highly corrosive or mild chemicals, acids, or solvents. Series MT pumps eliminate the conventional shaft seals found in most pumps. This means that there is no rotating seal to wear and allow the liquid being pumped to leak out. The pumping action may eventually fail, however, the liquid can never leak out. Series MT pumps are easy to install and operate, and are virtually maintenance-free.

Features and Benefits:

- Chemical-resistant

- Leak-resistant and sealless

- Rugged catilever design

- Runs dry to 30 minutes

Product Page:

Bulletins (PDF):

Penguin extended vertical immersible pumps are simple in design, efficient in performance, and self-priming when immersed in solution. Constructed completely of CPVC with glass molybdenum filled PTFE wear ring, or CPVC with PVDF impeller where in contact with the solution, this pump is suitable for pumping, agitating, filtering, or circulating acid and alkaline solutions, abrasive fluids, and other corrosive solutions up to 180° F maximum temperature. Penguin vertical pumps are versatile, easy to install, and require a minimal amount of tank space, thus saving valuable floor space.

Features and Benefits:

- CPVC Construction

- Optional PVDF Impeller available

- No metal contact

- Self-priming when immersed

- Dry run capability with PVDF impeller

Product Page:

Bulletins (PDF):

Filter Systems

Penguin in-tank filter systems are all purpose, compact, fully portable, corrosion resistant, and require no floor space. They are constructed so no metal is in contact with the solution. The Series A-A filter systems are available in CPVC, polypropylene, and PVDF. These systems incorporate an in-tank pump and a tank lip-mounted filter chamber. The Series A-A filter systems need not be removed from the tank for cleaning or replacing filter cartridges. These systems are available in 6 sizes to serve all small and medium volume tanks.

Features and Benefits:

- Leak-resistant

- Corrosion-resistant

- No metal contact

- Self-priming when immersed

- Uniques design - No liquid bypass

Product Page:

Bulletins (PDF):

Penguin in-tank filter systems are all purpose, compact, fully portable, corrosion resistant, and require no floor space. They are constructed so no metal is in contact with the solution. The Series A-B filter systems are available in CPVC and polypropylene, and certain models in PVDF. These systems are designed to be mounted entirely in-tank, which is especially recommended for precious metal filtration. The Series A-B filter systems need not be removed from the tank for cleaning or replacing filter cartridges. These systems are available in 11 sizes to accommodate larger volume tanks.

Features and Benefits:

- Leak-resistant

- Corrosion-resistant

- No metal contact

- Self-priming when immersed

- Uniques design - No liquid bypass

Product Page:

Bulletins (PDF):

Penguin in-tank pump / outside filter systems are ruggedly constructed and corrosion resistant. The Series A filter systems are designed for continuous operation with no metal to liquid contact and are versatile and easy to install, since both pump and filter chamber are independent units. Series A filter systems are available in CPVC and certain models in polypropylene and PVDF. Simple in design and efficient in performance, the Series A filter systems are recommended for all precious metal plating baths, electroless nickel and copper, as well as many acid and alkaline solutions. These systems are simple to clean and are designed for easy filter cartridge replacement.

Features and Benefits:

- Leak-resistant

- Corrosion-resistant

- No metal contact

- Self-priming when immersed

- Uniques design - No liquid bypass

- Heavy Duty operation

Product Page:

Penguin horizontal pump/filter systems are constructed of high temperature CPVC, and thus are excellent for most corrosive chemicals and capable of pumping solution to 180° F. Equipped with the Penguin Series HV horizontal volute pump or on larger systems, the Series HN centrifugal pump, and the rugged Penguin CPVC filter chamber, Series HF filter systems are designed for continuous high temperature operation. Series HF systems provide excellent filtration for electroless nickel and copper solutions. These systems are simple to clean and are designed for easy filter cartridge replacement.

Features and Benefits:

- CPVC Construction

- Chemical-resistant

- No metal contact

- High temperature operation

- Optional double mechanical seal with water flushs

Product Page:

Penguin magnetic-driven pump/filter systems are specifically designed with sealless pumps for filtering and circulating without the worries of mechanical seal leakage. Equipped with the Penguin Series M & MT polypropylene magnetic-driven pump and the rugged Penguin CPVC or polypropylene filter chamber, Series MF filter systems are designed for continuous trouble-free service. The smaller compact Series MF filter systems are excellent for complete corrosion resistant filtration in laboratories, pilot plants, and production applications. The larger filter systems provide a high volume, high pressure filter system to which casters can be added for portability. Simple in design and efficient in performance, these systems are recommended for acid and alkaline solutions.

Features and Benefits:

- Leak-resistant

- Corrosion-resistant

- No metal contact

- Self-priming when immersed

- Uniques design - No liquid bypass

Product Page:

Bulletins (PDF):

Penguin spacemaker filter systems are designed with sealless pumps to provide a complete, ultra compact, portable filter system without the worries of mechanical seal leakage. Equipped with the Penguin Series M polypropylene magnetic drive pump and the rugged Penguin CPVC or polypropylene filter chamber, Series SM filter systems are a simple, economical, and efficient method for filtering and circulating acid and alkaline solutions. The smaller compact Series SM filter systems are excellent for complete corrosion resistant filtration in laboratories, pilot plants, and production applications. These systems are simple to clean and are designed for easy filter cartridge replacement.

Features and Benefits:

- Leak-resistant

- Corrosion-resistant

- No metal contact

- Ultra Compact and efficient

- Optional priming chambers

Product Page:

Bulletins (PDF):

Penguin sealless polypropylene filter systems are designed for filtering critical solutions where all metal contact and mechanical seals must be eliminated. Series VF filter systems are equipped with a sealless self-priming pump and heavy duty CPVC or polypropylene filter chamber. These systems are recommended for continuous filtration to 180° F for most acid and alkaline solutions. Penguin Series VF filter systems are maintenance free, simple to clean, and are designed for easy filter cartridge replacement.

Features and Benefits:

- Self-Priming

- Leak-resistant

- No metal contact

- Continuous Filtration

Product Page:

Penguin bag filtration systems are designed to provide rapid, high velocity solution turnover, while removing contaminants that tend to surface load. In the Series BF filtration systems, the larger surface area of the single layered polypropylene filter bag provides significant longer life when compared to a graded density, string wound cartridge filter. Disposable bags are economical to use and may be easily discarded when spent or cleaned for reuse. Traditionally, bag filtration systems have been used with air sparging systems to constantly renew the plating solution that is coming in contact with the parts. A Penductor sparging system does the same thing, but refreshes the chemistry much faster, while giving you other benefits such as keeping solids in suspension for easier removal, more uniform temperature, thickness, and brightness. Since the Series BF bag filtration system is basically an open system, uniform agitation can be achieved without the need of a dedicated sparging pump.

Features and Benefits:

- Sealless pump

- Chemical-resistant

- No metal contact

- Choice of filter bag micron

- CPVC Construction

- High Temperature Operationn

Product Page:

Bulletins (PDF):

Penguin suction filter systems are ruggedly constructed and corrosion resistant. The Series A-SF filter systems are designed for continuous duty operation and trouble-free service. These systems are easy to install and maintain since there is only one moving part. Series A-SF suction filter systems offer filtration rates up to 3400 gph. They are constructed completely of CPVC, eliminating any metal contact.

Features and Benefits:

- Pumps, Filters and agitates

- Compact, Inexpensive, and dependable

- Versatile and portable

- Self-priming when immersed

- Immersible, Sealless, Bearing-free pump runs dry without damage

Product Page:

Bulletins (PDF):

Filter and Carbon Cartridges

Penguin wound filter cartridges provide true depth filtration and are available in a wide selection of media and cores, including pre-leached fibrillated polypropylene, to ensure temperature and chemical compatibility. The Series PF cartridges feature porosities from 0.5 micron to 150 micron, lengths from 3" to 40", and a variety of diameters.

Features and Benefits:

- True depth filtration

- Various core and media material combinations including pre-leached fibrillated polypropylene

- Chemical and temperature compatibility

- Wide choices of porosities

Product Page:

Bulletins (PDF):

Penguin filter sleeves are an alternative to standard wound filter cartridges. The Series PS filter sleeves are economical, reusable, and efficient when placed over its one-time purchased polypropylene core and caps. These sleeves can be precoated and backwashed several times before the retention of the sleeve is reduced. Series PS filter sleeves are available in porosities from 2 micron to 100 micron and in lengths from 10" to 40".

Features and Benefits:

- Economical

- Reuseable

- Efficient

- Long lasting

Product Page:

Penguin carbon filter cartridges are a one-step carbon and filtration treatment. These Series PC carbon cartridges eliminate the problems associated with loose carbon treatment and the need for a separate filtration system. The standard cartridge measures 2 3/4" O.D. with lengths varying from 4" to 40" and flow rates up to 2 1/2 gpm. These Series PC carbon cartridges are designed to be used in either single or multi-tubed vessels. These cartridges are available in 4 different styles. Style GC is an outer wound cartridge which utilizes a special high grade activated granular carbon with a very low sulfur content. Style CP is also an outer wound cartridge which features layers of paper impregnated with activated powdered carbon. Style C is a porous polyethylene shell containing high grade activated granular carbon. Style M features an outer layer of polyolefin webbing with an impregnated carbon powder interior.

Features and Benefits:

- Organic impurity removal

- Non-contaminating

- Choice of packed granular or impregnated powder carbon cartridges

- High grade activated carbon

- Second filter cartridge replacement

Product Page:

Bulletins (PDF):

Penguin pleated filter cartridges are an alternative to string wound or spun molded filters. These Series PP pleated cartridges are economical, multi-use, premium quality products that are available in various micron ratings ranging from 50 micron nominal down to .10 micron absolute. End cap configurations include D.O.E. (double open end, flat gasket) and S.O.E. (single open end, external double 222 0-ring/button end cap). Filter medias available include self-bonded fine diameter polypropylene fibers as well as membranes constructed of polypropylene, nylon, or PTEF. Series PP pleated cartridges contain no surfactants or binders that can break down, leach out, or permit the typical problems of channeling and media migration. Maximum effective open surface areas allow for high flow rates at reduced pressure losses, as well as high dirt holding capacity, long service life, large throughputs, and lower operating costs. Series PP pleated cartridges may be used as either prefilters or as final filters for bulk and point-of-use filtration. They are most appropriate for use when high efficiency filtration and economy are crucial.

Features and Benefits:

- Nominal and Absolute particle retention ratings

- Superior flow characteristics

- High dirt holding capacity

- Many lengths and cartridge styles

Product Page:

Bulletins (PDF):

Precious Metal Recovery Systems

Penguin precious metal recovery systems are a simple and economical method for reclaiming gold and other precious metals from processing rinse water and drag out tanks. The exchange resin of standard porosity extracts precious metals as well as all positive and negative charged ions from processing wastes. The Series SR systems are used with rinse capacity tanks of 50 gallons and smaller. Up to three troy ounces of precious metal can be recovered per pound, meaning it pays for itself after its initial use.

Features and Benefits:

- Recovers 99% of Precious metals

- Improves purity of rinse

- Low initial cost

- Pays for itself during normal plating sequence

- Selection of sizes to fit all plating tanks

- Longer life before resin changes

- Depth filtration available

Product Page:

Penguin precious metal recovery systems are a simple and economical method for reclaiming gold and other precious metals from processing rinse water and drag out tanks. The exchange resin of standard porosity extracts precious metals as well as all positive and negative charged ions from processing wastes. The Series MR systems are used with rinse capacity tanks of 50 gallons or larger. Up to three troy ounces of precious metal can be recovered per pound, meaning it pays for itself after its initial use. Series P pumps are also available in conjunction with the resin beds, thus eliminating the magnetic driven pump.

Features and Benefits:

- Recovers 99% of Precious metals

- Improves purity of rinse

- Low initial cost

- Pays for itself during normal plating sequence

- Selection of sizes to fit all plating tanks

- Longer life before resin changes

- Depth filtration available

Product Page:

Tank and Drum Mixers

Penguin mixers are designed to handle a wide range of chemicals for both tanks and drums without difficulty. Series PM propeller mixers are completely constructed of 316SS shafts, couplings, and propellers. Series PM turbine mixers utilize the same 316SS shaft and coupling, but are only available with a polypropylene turbine. For a mixer where no metal is in contact with the solution, a polypropylene propeller and sleeved shaft are supplied. Series PM mixers are available in four different mounting styles including bracket mount, clamp mount, flange mount, and thread mount.

Features and Benefits:

- Economical and Efficient

- Use in both tanks and drums

- 316SS shaft and couplings

- 316SS or polypropylene propellers / polypropylene drum turbines

- Four mounts available

Product Page:

Bulletins (PDF):

Filter Housings and Syphon Pumps

Penguin filter housings are constructed of reinforced polypropylene consisting of cap, sump, and sealing ring for rust and corrosion resistance and extra durability. The hot water/high pressure housing uses a special glass reinforced nylon. The simplified design of the Series PH filter housings offers easy installation and fast cartridge change, and accepts standard piping for in-line installation. These filter housings provide a long service life of dependable performance. Penguin Series PH filter housings must pass a cyclic pressure test designed to simulate line hammer of 250,000 cycles from zero to 150 psi line pressure at a rate of 12 to 20 cycles per minute without failure to the housing.

Features and Benefits:

- Low Cost

- Simplified design

- Built-In adaptability

- Optional Hot / High pressure

Product Page:

Penguin drum/container pumps are designed in two basic styles - manual and siphon. The Series DP plastic manual drum pumps are available in high-density polypropylene and can pump from 8-20 ounces per stroke. They are designed to fit 5, 15, 30, and 55 gallon drums. The Series DP metal manual drum pumps are designed to fit 2" IPS female connectors and are available in various materials from cast iron to 316SS. The maximum flow rate for the metal manual pumps is 28 GPM. The Series DP plastic siphon drum pumps are totally constructed of polyethylene and are designed for 1, 2 1/2, 3, 5, and 55 gallon drums. The maximum flow rate for the siphon pumps is 7 GPM.

Product Page:

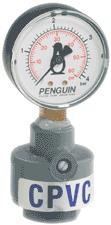

Pressure Gauge and Guards

Penguin pressure gauge guards have a unique, compact, molded design. This low profile design fits well in tight spaces such as reel to reel systems or other automatic systems. Consisting of two threaded fluid chambers, there is no possibility of leakage due to uneven screwed components in the Series PGG gauge guards. Each piece contains a matching groove, which confines the true O-ring incorporated on the O.D. of the impermeable diaphragm. The internal parts of the Series PGG gauge guards in contact with the diaphragm have a large radius, thus preventing any damage to or shearing of the diaphragm. The choice of materials permits these gauge guards to be utilized on highly corrosive and ultra-pure solutions. Guards can also be purchased separately from gauges.

Features and Benefits:

- Choice of Material: Body - CPVC, Polypropylene or PVDF Diaphragm - Viton

- Maintains System Purity/ Leak-Resistant

- Molded Thread Connections Between Joints

- No Metals Utilized Internally or Externally

- Confined O-Ring Seal and Impermeable Diaphragm

- Bleed for Filling/No Air Entrapment for Most Accuracy

- Flats on Both Molded Parts for Proper Tightening

Product Page:

Penductor Systems

Penguin Penductor systems are designed for in-tank mixing using the tank fluid as the mixing medium for solution agitation. Simple in design, the Series PES Penductor systems are easy to install, operate, and maintain. Penductors utilize the fluid inside the tank reservoir as the "motive" fluid, which is defined as the fluid flowing through the Penductor nozzle. The high velocity motive fluid entrains the liquid near the suction openings of the Penductor, and mixes this liquid thoroughly as it passes through the diffuser. The resulting plume of mixed fluid, flowing at an intermediate velocity, now proceeds to mix and agitate the remaining tank liquid. The Series PES Penductor systems are completely piped and ready to be attached to the discharge of the motive driving pump.

Features and Benefits:

- Available as Systems with Pumps, Kits or Nozzles Sold Separately

- Deluxe Model Features Adjustable Nozzles

- No Metal to Solution Contact

- Perfect Solution for Large Tanks

- Induces 4 Gallons Extra for Every Gallon Passing Through Nozzle

Product Page:

Bulletins (PDF):

Penguin Penductor sparging eductors offer a new twist to the current eductor craze. Based on established eductor principles, the Series PE Penductor was designed especially for industrial sparging applications. The nozzle was designed utilizing the same orifice size as a typical 3/8" NPT tank mixing eductor, with a larger connection size, thus giving you the same flow characteristics with less pressure drop. This can reduce the horsepower required on larger systems. The larger connection size allows you to use standard PVC reducing tees without extra bushings or reducing couplings, thus saving you valuable tank space. The diffuser was designed with a larger plume dispersion angle for more uniform agitation and a lower profile to allow you to utilize your tank space more efficiently. The result, the Penductor, a more efficient space-saving eductor made specifically for the surface finishing industry.

Features and Benefits:

- Flows Comparable with Conventional 3/8" Tank Mixing Eductors

- Lower Profile Helps Save Valuable Tank Space and Makes for Easier Retrofits

- Larger Connection Sizes Eliminate Need for Multiple Bushings When Using Standard Fittings or P-Series Pump

- Larger Plume Dispersion Angle Helps Eliminate Dead Spots Between Eductors

- Maximum Temperature 280 °F

Product Page:

Bulletins (PDF):