Distributed by:

Equipment Overview | Filter Pump Industries / Penguin Pump | Process Technology

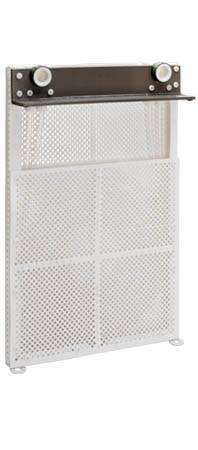

X Series, Fluoropolymer Heating Cooling Coils

1/4 Pro-Coil

| SURFACE AREA Square Feet | CONNECTIONS | SIZE A In./(mm) | SIZE B In./(mm) | SIZE C In./(mm) | SIZE D In./(mm) | 1/4 Pro-Coil | SHIP WEIGHT Lbs/(kg) |

|---|---|---|---|---|---|---|---|

| 2.25 | 1/2" FNPT | 11.5 (292) | 11.5 (292) | 1.5 (38) | 17.5 (445) | X1-12-12-18-F | 10 (4.5) |

| 4.50 | 1/2" FNPT | 11.5 (292) | 11.5 (292) | 2 (51) | 17.5 (445) | X2-12-12-18-F | 11 (5) |

| 4.50 | 1/2" FNPT | 15.5 (394) | 15.5 (394) | 1.5 (38) | 21.5 (546) | X2-16-16-22-F | 13 (6) |

| 9.25 | 1/2" FNPT | 15.5 (394) | 15.5 (394) | 2 (51) | 21.5 (546) | X4-16-16-22-F | 14 (6.5) |

1/2 Pro-Coil

| SURFACE AREA Square Feet | CONNECTIONS | SIZE A In./(mm) | SIZE B In./(mm) | SIZE C In./(mm) | SIZE D In./(mm) | 1/2 Pro-Coil | SHIP WEIGHT Lbs/(kg) |

|---|---|---|---|---|---|---|---|

| 6.00 | 1" FNPT | 17.5 (445) | 17.5 (445) | 2 (51) | 23.5 (597) | X2-18-18-24-F-LP | 18 (8) |

| 12.00 | 1" FNPT | 17.5 (445) | 17.5 (445) | 3.25 (82.5) | 23.5 (597) | X4-18-18-24-F-LP | 22 (10) |

| 18.00 | 1-1/2" FNPT | 17.5 (445) | 17.5 (445) | 4.5 (114) | 23.5 (597) | X6-18-18-24-F-LP | 26 (12) |

| 24.00 | 1-1/2" FNPT | 17.5 (445) | 17.5 (445) | 5.75 (146) | 23.5 (597) | X8-18-18-24-F-LP | 30 (13.5) |

| 11.50 | 1" FNPT | 23.5 (597) | 23.5 (597) | 2 (51) | 29.5 (750) | X2-24-24-30-F-LP | 24 (11) |

| 23.00 | 1" FNPT | 23.5 (597) | 23.5 (597) | 3.25 (82.5) | 29.5 (750) | X4-24-24-30-F-LP | 30 (13.5) |

| 34.50 | 1-1/2" FNPT | 23.5 (597) | 23.5 (597) | 4.5 (114) | 29.5 (750) | X6-24-24-30-F-LP | 36 (16.5) |

| 46.50 | 1-1/2" FNPT | 23.5 (597) | 23.5 (597) | 5.75 (146) | 29.5 (750) | X8-24-24-30-F-LP | 42 (19) |

Features and Benefits

SUPERIOR CHEMICAL RESISTANCE:- For heating or cooling of most aqueous acid and alkaline solutions. Check solution guide or consult with your chemical supplier for proper sheath material selection.

- All wetted parts of fluoropolymer (FEP, PFA or PTFE) construction.

- Heavy duty CPVC mounting bracket.

- 1/8-inch thick perforated guard helps protect the coil from damage.

- Heavy wall tubing improves circulation and minimizes pressure drop. Larger coils constructed of ½-inch (13mm) tubing, smaller coils have ¼-inch (7mm) tubing.

- Integral inlet and outlet manifolds for single point connections greatly reduce the potential for leaks and simplify installation.

- 2.25 ft2 to 46.5 ft2 of exchange area standard.

- Eliminates stray currents in the tank.

- Standard coils are made from FEP (Fluorinated Ethylene Propylene) and rated up to 30 PSI steam service.

- PFA (Perfluoroakoxy resin) coils are available for steam service up to 60 PSI.

- 10 PSI minimum steam pressure required for operation.

- Consult factory regarding pressure reduced applications.

- Anti-floatation brackets.

- Special sizes.

- Special manifold configurations.

- L-shaped configurations for bottom heat applications.

- Dual coils for both heating and cooling.

Downloads: